Pole 20 x 16 Shed Creation Schematics - How To Effortlessly Plan & Craft Your Dream Garden Shed Step by Step

Place scrap piece with the joist hanger on ledger, centered on first pencil mark. There were three windows on right side and no windows on left of the structure. Make sure the side shiplaps would cover the front and back as you did before. It needs to withstand greater wind force but sheds rain, snow, and debris more quickly. Make sure you by the best materials you could afford and check if they are in a good condition. The most important thing to remember is to use the tools (https://shedblueprintsdiy.com/shed-blueprints-10x12-free-plans-to-build-a-10x12-shed) you are most comfortable with as this will craft project go much more quickly.

Make window by assembling a simple wood frame to hold a piece of double-strength glass. The front and back overhangs highlight neat designs and protect the walls from heavy precipitations. Cut the dimensional lumber to length using a circular saw. This includes cleaning supplies and other products that were taking up space in my home. To install a tapcon use an appropriate sized masonry bit and then screw tapcon into hole. They're readily available and come with a good guarantee. Removing the ceiling studs leaves the porch with an open cathedral ceiling, but it requires that the structural support of the joists be replaced with some other structural alternative.

And then door could be hanged. Hardie board is cement siding that you hang with screws and comes in different colors. This will allow you to add your own trim for a custom look. Each (learn more here) screw has a dish shaped washer and rubber gasket to seal hole it goes into. The floor might feel spongy or bouncy underfoot, or you might notice a sag in middle. A dormer projects from a sloped roof and has its own walls and roof, but the dormer's walls and roof are often supported by main roof rather than the building's walls and consequently require special framing.

Each must be properly framed in for maximum structural integrity. Remember to sink them below the frost line. After reading this guide, you would have all necessary information to build a solid outbuilding floor that would last the life of your shed. The post have to be countersunk to build clearness for heads of the bolt and tapcon. Run your choice of insulation in your studwork. This method proved easy enough in practice. Siding is not only important because it keeps weather out, but it's part that everyone sees so it's key to do a thoughtful job. Before starting actual project, we recommend you to study the local building codes, as there are many legal requirements you have to comply with.

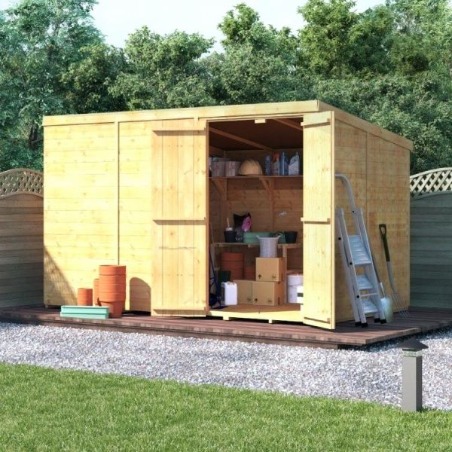

This guide is not complete perfect how to do concrete guide. This will square up your wall perfectly. They're usually constructed of poured-concrete piers or buried wooden posts. Overhangs should now be installed if desired. This step by step DIY woodworking project is about free pole barn plans. Make sure you check out the rest of plans to see alternatives and more projects for your garden. Its structural integrity, however, is only as good as the combined strength of floor's members. We had been making shelves and small furniture pieces out of pallets for a couple months and started discussing using pallets as our building material.

This could be as simple as taking your garden hose and using it to mark the outline of outbuilding floor on your grass or you could use 4 stakes hammered into the grass. In addition, use a good jigsaw to slice out the door opening. Attach them to the underside of the hardwood joint with three or four 2 inch screws. The spacing between beams depends on whether they support a hardwood subfloor or deck boards. Because every truss in the floor plays a specific role in dispersing load, you can't just knock one out and create another in its place.

Use joist hangers to lock beams to frame. Massive red-pine logs and an overhanging gable frame a side window trimmed in mahogany. First, measure and trim your top and bottom plates. Then set up for next angle and construct all those cuts. A complication this strategy caused was that the door would now have the weight and heft of a 7' x 4' stucco wall. Sand wooden surfaces with 120 grit sandpaper, before applying primer and several coats of paint to siding and studs. The finished slab is strong enough to support vehicles and sits on the ground so it's easy to drive in to.

To clad these frames, use same method as other walls with a 50mm overlap where the side walls would be attached to the front frame, again to hide frame.